FR-E Series

Simple, powerful, and compact inverter FR-E series.

Offers remarkable usability and top level driving performance! All-rounder in a compact body.

Enquiry about FR-E Series

Enter the security code shown above

FR-E700

Achieving the top level of driving performance in compact body, the inverter became more powerful.

Advanced magnetic flux vector control enables accurate start-ups of general-purpose industrial machines.

High torque 200%/0.5Hz is realized by Advanced magnetic flux vector control (3.7K or less)

By the advancement of General-purpose magnetic flux vector control to Advanced magnetic flux vector control, top level of driving performance became possible.

Since V/F control and General-purpose magnetic flux vector control operations are available, operation after replacement of the conventional model (FR-E500 series) is ensured.

For the 5.5K to 15K, 150%/0.5Hz torque is realized.

Speed/torque characteristics example

Advanced auto tuning

Many kinds of three phase induction motors can be optimally controlled with Mitsubishi’s original “non-rotation” auto tuning function.

High precision tuning is enabled even when a test operation of a machine cannot be performed at parameter adjustment.

Advanced magnetic flux vector control is ideal for a lift in an automated-storage system which requires high torque at low speed.

Short time overload capacity is increased (200% 3s)

Short time overload capacity is increased to 200% 3s (200% 0.5s for the conventional model).

Overcurrent trip is less likely to occur.

When a bogie runs over a bump, the impact can be beared by this function.

Torque limit/current limit function

Improved torque limit/current limit function provides a machine protection, load limit, and stop-on-contact operation.

Using the torque limit function, machine breakage from overload can be avoided.

For example, edge chipping of a tool can be avoided.

Improved regeneration capability

A brake transistor is built-in to the 0.4K to 15K.

Connecting an optional brake resistor increases regeneration capability.

Excellent usability

mproved setting dial

Easy setting with the Mitsubishi Electric setting dial.

● Displayed numbers can be jumped by turning the setting dial quickly, and numbers can be changed one by one by turning it slowly, enabling speedy parameter setting.

● The nonslip setting dial is easier to turn.

Easy setting mode

According to the desired command sources for start frequency and speed, Pr.79 can be set in simple steps.

With a provided USB connector, setting is easily done from a personal computer using FR Configurator

An USB connector (mini-B connector) is provided as standard. The inverter can be easily connected without a USB-RS-485 converter.

Wizard (interactive) function of FR Configurator (inverter setup software) provides setting support.

In addition, a high-speed graph function with USB enables high speed sampling display.

Enclosure surface operation panel FR-PA07 (option)

Optional enclosure surface operation panel (FR-PA07) can be connected.

In addition, an operation panel for conventional model (FR-E500 series) can be connected.

The operation panel of the inverter cannot be removed.

A parameter unit connection cable (FR-CB20□) is separately required.

Parameter unit FR-PU07/FR-PU07BB(-L) (option)

The FR-PU07/FR-PU07BB(-L), an optional parameter unit, can be connected as well.

A parameter unit connection cable (FR-CB20□) is separately required.

(Parameter unit connection cable FR-CB203 (3m) is enclosed with FR-PU07BB(-L).)

● Setting such as direct input method with a numeric keypad, operation status indication, and help function are useful.

The display language can be selected from 8 languages.

● Parameter settings of maximum of three inverters can be stored.

● A battery pack type (FR-PU07BB(-L)) allows parameter setting and parameter copy without powering on the inverter.

To use a parameter unit with battery pack (FR-PU07BB) outside of Japan, order a “FR-PU07BB-L” (parameter unit type indicated on the package has L at the end).

Full of useful functions

● Automatic restart after instantaneous power failure function with frequency search

Detection of coasting speed (frequency search function) prevents the motor speed from decreasing at a restart, starting the motor smoothly with less output current.

● Power-failure deceleration stop function/operation continuation at instantaneous power failure function

The motor can be decelerated to a stop when a power failure or undervoltage occurs to prevent the motor from coasting.

This function is useful to stop a motor at power failure as a fail safe of machine tool, etc.

With the new operation continuation function at instantaneous power failure, the motor continues running without coasting even if an instantaneous power failure occurs during *1

● Brake sequence mode …… is useful for mechanical brake control of a lift.

● Regeneration avoidance function …… prevents regenerative overvoltage in a pressing machine.

● Optimum excitation control …… can save more energy with the maximum motor efficiency control.

● Main circuit power supply DC input …… can be connected to DC power supply.

● Enhanced I/O terminal function …… supports switchover of analog input (voltage / current).

● Password function …… is effective for parameter setting protection.

and so on

- *1 : The inverter may trip and the motor may coast depending on the load condition.

Energy saving for fans and pumps

● Load pattern selection (Pr. 14)

Optimal output characteristics (V/F characteristics) for application or load characteristics can be selected.

● Optimum excitation control (Pr. 60)

With Optimum excitation control to achieve the highest motor efficiency, further energy saving can be achieved.

FREQROL-E800

Useful functions for each of the design, operation, and maintenance processes of systems

FR-E800 inverters have various functions to attract more customers by offering safe and reliable operation for a long time. This is the time to start innovation in the fields of manufacturing.

Wide range of applications

Engineering software for further ease of operation

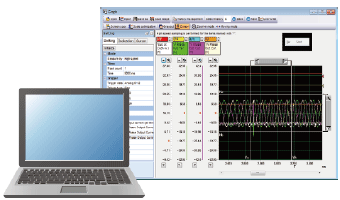

FR Configurator2 for further ease of operation

Using FR Configurator2, easy-to-use software assisting anything from setup to maintenance, much more useful functions are available for users.

| Function | Free trial version |

|---|---|

| Parameter list | ○ |

| Safety parameter setting(FR-E800-SCE) | ○ |

| Diagnosis | ○ |

| AI fault diagnosis | × |

| Graph | × |

| Batch monitor | × |

| Test operation | ○ |

| I/O terminal monitor | × |

| Function | Free trial version |

|---|---|

| Convert | △ |

| Developer | × |

| USB memory parameter copy file edit | × |

| Ethernet parameter setting | ○ |

| iQSS backup file conversion | ○ |

| Help | ○ |

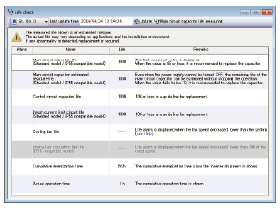

- Life diagnosis check

Parts service life data is displayed in a dedicated window. A warning icon is shown in the alarm field of the parts recommended for replacement.

This can be used as a guideline to replace long life parts.

- Graph function—trace function

Graph display and log analysis are available using the stored trace data.

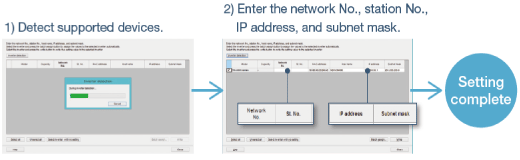

- Ethernet parameter setting

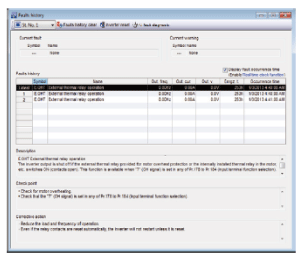

- Diagnostics (Fault history)

Further facilitating operation with your smartphone

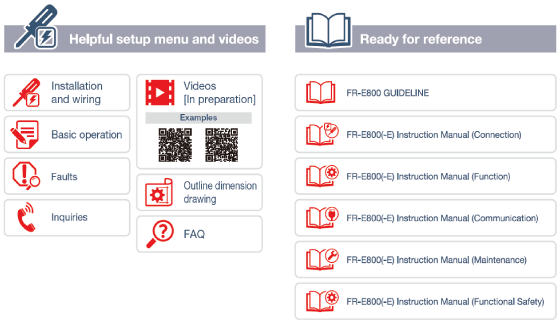

- Setup information web page

Manuals, setup videos, and outline dimension drawings are available.

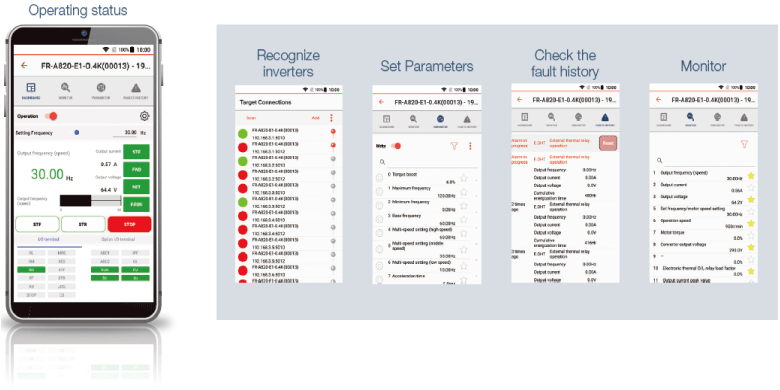

- Mobile app

Users can easily monitor the inverter operation by checking data such as the running frequency and status of input and output terminals at a glance in one screen.

Wireless communication equipment must be prepared in the system that includes the inverter.

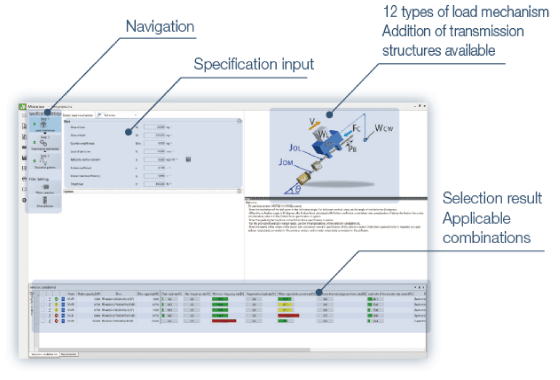

Further facilitating operation with Drive System Sizing Software Motorizer

Applicable combinations include inverters, sensorless servo drive units, and AC servo amplifiers.

The most suitable combination can be selected from the selection result. The software also supports multi-axis systems.

Twelve types of load mechanism such as a ball screw or a rack and pinion are selectable.

Selection is available by following the steps from 1 to 3.

When users include the power regeneration common converter or other applicable converter, the capacity of the converter can be selected at the same time.

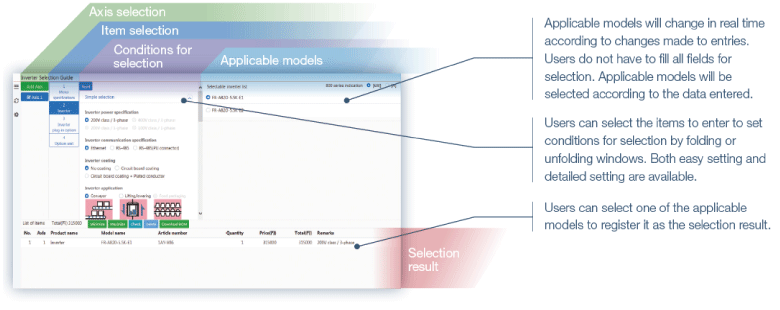

Further facilitating operation with the selection guide software

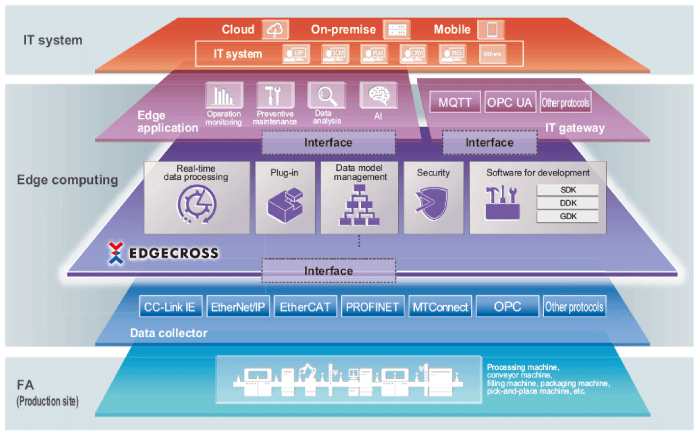

Further facilitating operation with Edgecross

- Integration and processing of data sent from various devices and systems in production lines

- Real-time feedback to production sites

- Monitoring of field devices based on the know-how of production sites

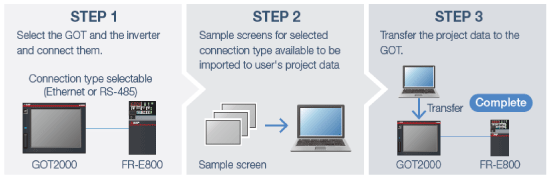

Further facilitating operation with GOT interaction functions

Enhanced compatibility between inverters and the GOT (human machine interface) brings various benefits to users.

Connection with the GOT2000 series can be established just by setting the station number. Other necessary settings are automatically done.

- Less time spent on screen design work by importing sample screens

Using sample screens enables easy startup of the system.

- *1:Sample screens are included in the GT Works3 package, or can be downloaded at Mitsubishi Electric FA Global Website.

Sample screens are available for FR-E800 and FR-E800-E. FR-E800-SCE is to be supported.

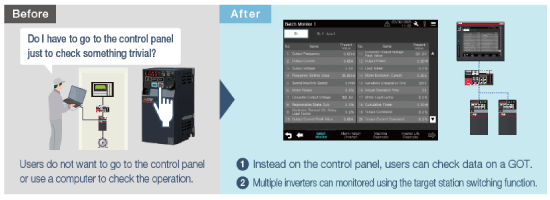

- Improving work efficiency without using a computer

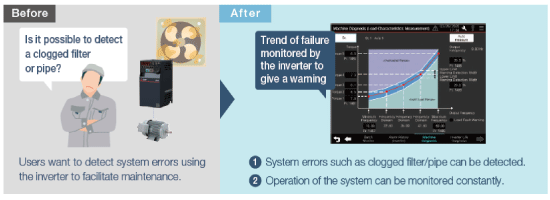

- Immediate warning of system errors

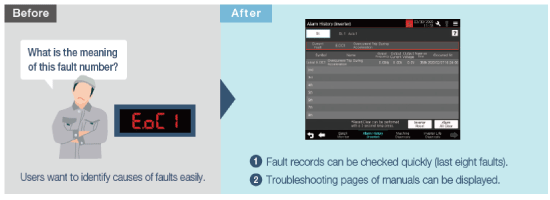

- Reducing downtime by interacting with the GOT

When a fault occurs, it is possible to identify the cause immediately, which contributes to downtime reduction.

Related products

Controllers

Medium-voltage Power Distribution

Medium-voltage Power Distribution

Medium-voltage Power Distribution

Computerized Numerical Controllers(CNCs)

Controllers

Energy Saving Supporting Devices

High-voltage Alternating