Thick Flat Spray Semi-Fine Fog Nozzles DDA series nozzles

| Pipe conn. size | Rc1/4–Rc1/2 |

|---|

| Spray angle | 75°–125° (*1) | Spray capacity | 0.14–57.3 ℓ/min | Supply air type | Compressed air |

|---|

| Liquid feeding system | Liquid pressure | Mean droplet diameter | 15–200 μm (*3) | Air consumption | 17–610 ℓ/min, Normal |

|---|

| Air pressure | 0.1–0.4 MPa | Free passage diameter | 2.0–7.0 mm (*2) |

|---|

Enquiry about Thick Flat Spray Semi-Fine Fog Nozzles DDA series nozzles

Enter the security code shown above

Features

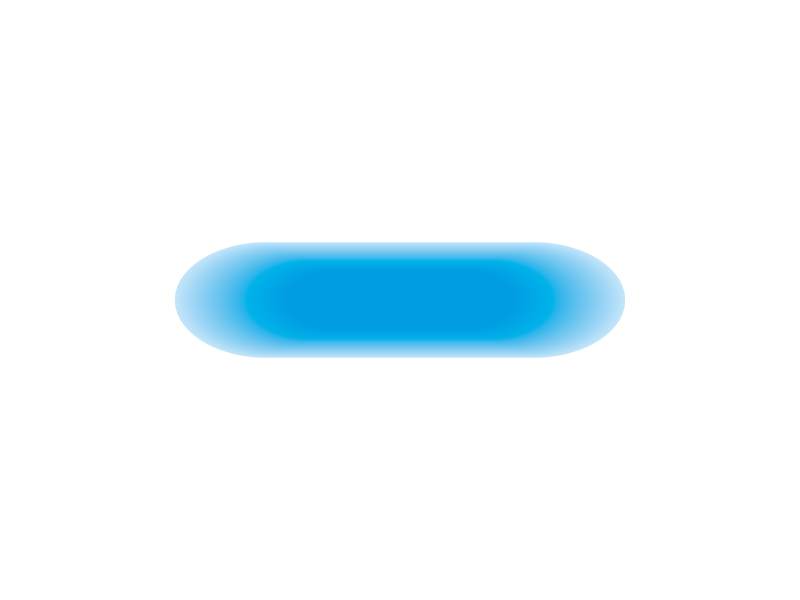

• Thick flat spray pneumatic nozzle producing a large volume of semi-fine atomization with a mean droplet diameter of 50 μm or more (*3).

• Liquid pressure type under the liquid pressures of 0.07–0.7 MPa.

• Large turn-down ratio with minimal variation in spray angle.

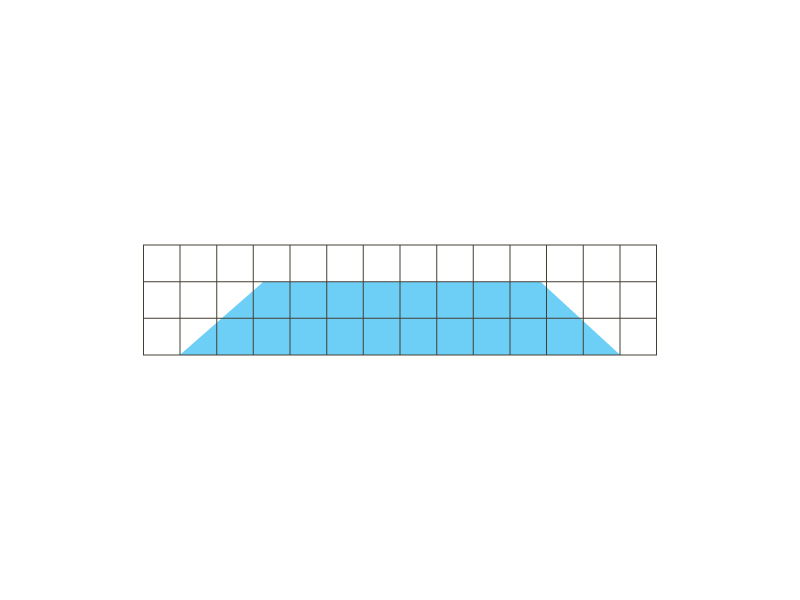

• Uniform distribution suitable for multiple-nozzle arrangements.

• Thicker flat spray pattern covers wider area.

• Large free passage diameter minimizes clogging.

• Spray angle of 75°, 80°, 100°, 110°, or 125°.

*1) Criteria for spray angle measurement differs depending on nozzle codes.

*2) Free passage diameter of nozzle orifice.

*3) Measured by Fraunhofer diffraction method.

Applications

Cooling: Gas, steel plates, steel pieces, pipes, moldings, etc.

[Steelmaking industry]

Steel making process: Cooling continuous casted steel (bloom, slab short side, billet), cooling roll of casting machine

Rolling mill process: Cooling steel plate on continuous annealing line, roll in heat treatment, and magnetic steel

Industries in which this nozzle is used

• Steelmaking

• Pollution Control

Product specifications

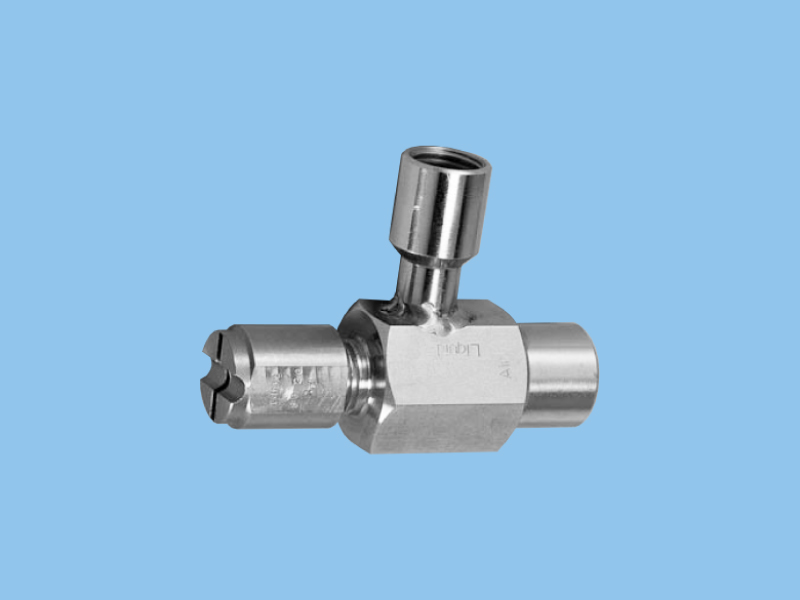

| Structure | • Comprising four parts: Nozzle body, pipe, mixing adaptor, and liquid socket. • Internal mixing type designed to mix compressed air and liquid inside the nozzle (Pre-mix type: compressed air and liquid are already mixed inside the nozzle adaptor). • Liquid pressure type. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Material | • Nozzle body: Stainless steel 303 • Other parts: Stainless steel 304 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Mass |

See below |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Outer dimensions |

①Nozzle body ②Pipe ③Mixing adaptor ④Liquid socket

・ L1 shows the standard length, which is shortest, and the longest length is 1,500 mm.

・ Pipe connection sizes for air and liquid are the same.

・ Each mass shows DDA with standard length (L1). For longer lengths, add the corresponding mass (listed below) for each 100 mm of length, according to Nozzle Thread Size 1. (When the Nozzle Thread Size 1 is 1/8F, mass per 100 mm is 50 g, for 1/4F it’s 80 g, for 1/2F it’s 160 g, for 3/4F it’s 220 g)

Note: Appearance and dimensions may differ depending on nozzle codes and materials. Please contact us for details. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Related products

IKEUCHI

IKEUCHI

IKEUCHI

IKEUCHI

IKEUCHI

IKEUCHI