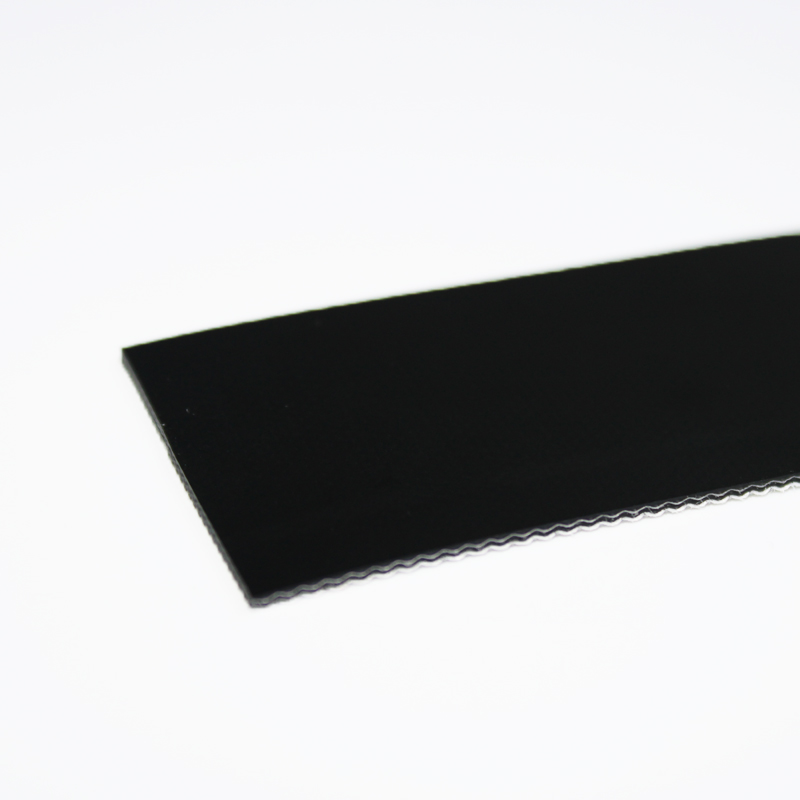

SL-S3827

Enquiry about SL-S3827

Enter the security code shown above

| No. of Plies | Weight (Kg/m2) | Total Thickness (mm) | Minimum pulley diameter (mm) Knife edge | Belt support | Top friction coefficient | Backside Friction coefficient | Unpackaged food | Non-Fray | incline | Ultra anti- static | Applicable operating temperature ( ํ C) | Maximun applicable width (mm) | Previous product ramarks | ||||

| Finger | Hot lap | Cold lap | Table | Roller | Trough | ||||||||||||

| 2 | 1.5 | 1.4 | 35 | 40 | 45 | 〇 | 〇 | △ | 0.25 | 0.15 | 〇 | – | △ | 1200 | -10~80 | 1800 | 88CW5/W5JE FF |

〇:Suitable (functional)

△:May be suitable. Please contact Bando or your distributor.

×:Not suitable

-:Not functional

Hot joint is recommended. Delicate fabric material is used, and unprocessed belt edge and cold joint may result in unstable joint strength.

S Series for Specialty Conveyance

- Heat resistance

Belt surface temperature is the basis for determining heat resistance temperatures. The belt surface temperature is usually lower than the material being conveyed, so belts may be used even if the material temperature exceeds the temperature range for the belt. If ambient temperatures are high, the belt surface temperature should conform to the ambient temperature. - Antifungal PVC for food 1

Bando offers belts with PVC covers that meet Article 370 standards of the Food Sanitation Act of the Ministry of Health and Welfare. The properties of these PVC-covered belts are suitable where antifungal performance is required, as mold is less likely to occur. - Oil resistance

The polyurethane used as a cover material for SUNLINE belts is relatively resistant to mineral oil and food oils. Specially formulated oil-resistant PVC also provides resistance to machine oil and other similar lubricants. See pages 41 and 42 for more information about resistance to specific oils and chemical agents. If the list does not include the substance you’re looking for. we can verify the belt’s resistance if you provide a sample oil or chemical agent for us to test. Please contact a Bando Chemical Industries sales company or dealer for more information. - Antistatic performance

Static electricity is generated when belts move due to friction between the belt and the belt supports. Belts develop an electric charge as the result of this static electricity, but the canvas and resin materials used in SUNLINE belts incorporate features designed to reduce the effect of this phenomenon.

Joining Methods

SUNLINE Belts can be joined using hot or cold jointing methods. Joint types include finger, overlap, lace (fastener), but most common are finger or overlap.

- Finger joints

Small pulleys and knife edges require flexibility, so smooth belt surfaces and precision thickness is required. This type of joint is not appropriate for high temperature areas or for roller applications with clinging matter on the belt.

- Overlap joints

Overlap joints include hot joint and cold joint. Hot joint is more durable. Hot wrap is generally used where heat and humidity resistance is required. With one ply belts, finger joint is recommended because of better appearance and higher flexibility compared to hot joint and cold joint, which may cause unevenness on belt surface.

- Double Finger joints (specialty)

Combination Finger and overlap joint. Easy use on small pulleys, and strong against foreign matter. Applicable for 2 ply belts. - Lace joints

Simple joining method using metal clips or fasteners to easily join and replace belts. However, joint strength is inferior to hot and cold joints.

Skiver joints are also possible. Please contact Bando or your distributor.

V-Guide Processing

V-guides can be used to prevent snaking. They can also be used to prevent products from falling off a conveyor by attaching them to the top of the belt, as V-guides are longitudinally Flexible.

Features

- Effective in snaking and spillage prevention

- Heat vulcanization allows for use on small pulleys

- Nontoxic and odorless

Standard PU and humidity and heat resistant PU meets Article 370 standards of the Food Sanitation Act of the Health and Welfare Ministry

Related products

BANDO

BANDO

BANDO

BANDO

BANDO

BANDO